Automotive exterior solutions to meet your needs

At Mitsubishi Chemical Group, we create automotive exteriors that capture attention even while facing harsh environmental conditions with innovative solutions designed to meet our customers needs.

At Mitsubishi Chemical Group, we create automotive exteriors that capture attention even while facing harsh environmental conditions with innovative solutions designed to meet our customers needs.

Our material scientists are passionate about reimagining chemistry that increases safety while decreasing our collective impact on the earth. Using composites, performance polymers, and engineering plastics paired with specialty additives and coatings, we develop beautiful components that stand the test of time.

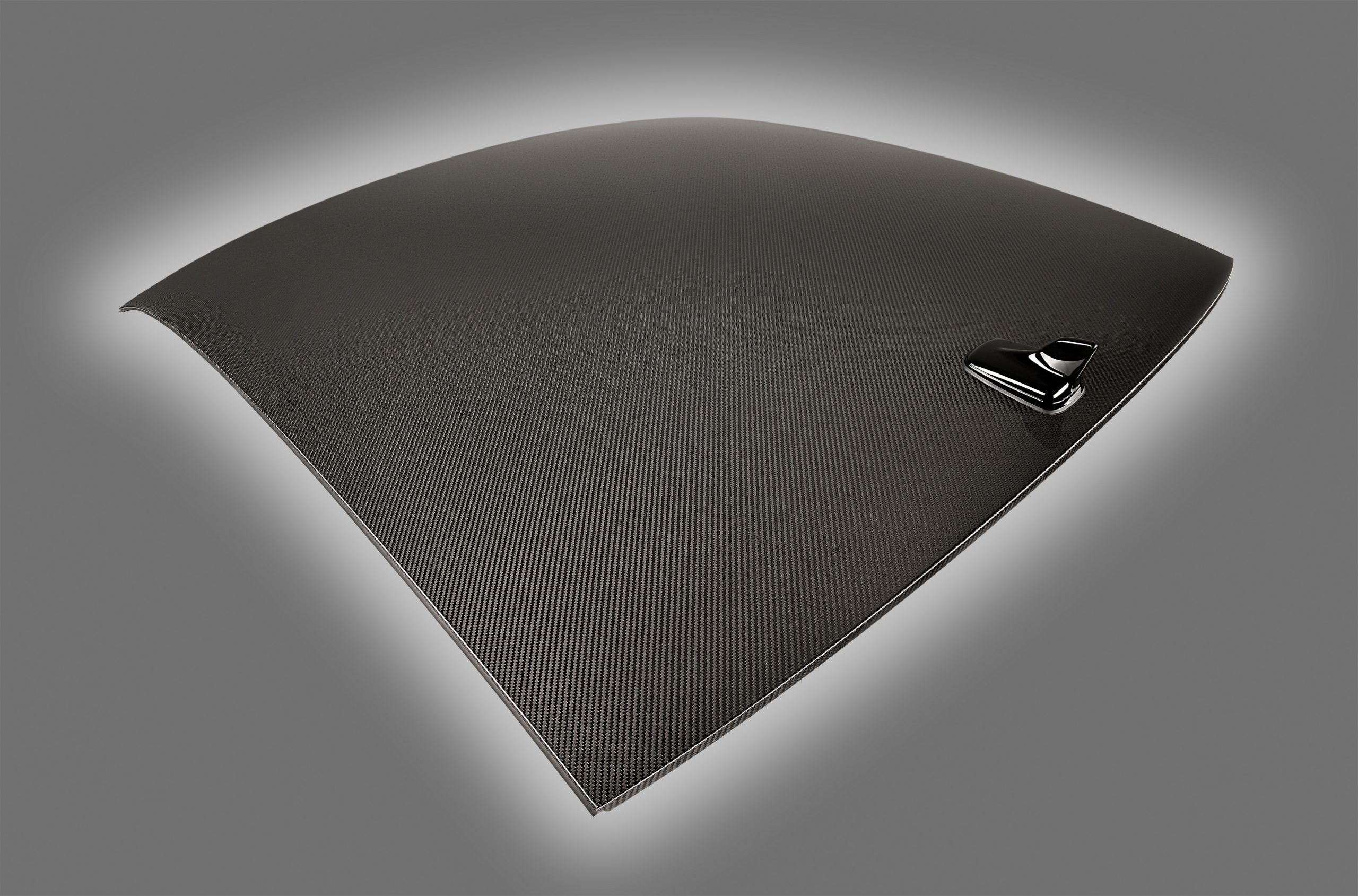

Mitsubishi Chemical Group’s Carbon Fiber Forged Molding Compound (CF FMC) won the 2021 SPE ACCE Innovation Award for its roof application. CF FMC was selected for the combination of high corrosion and heat resistance, dimensional stability, and high impact strength. In the GR Yaris roof, the material lowers the center of gravity, an important attribute for sports grade vehicles. CF FMC is available in various resin and fiber types for optimal design applications, with strength and modulus properties comparable to aluminum alloys. Additionally, the material cost for Mitsubishi’s material is lower than prepreg or RTM, also providing higher productivity.

Through our fully integrated carbon fiber supply chain, unique material proposal and quality management, Mitsubishi Chemical’s CF-FMC is an ideal choice for lightweight primary & secondary structural applications, closure panels and even visual CFRP applications.

Mitsubishi Chemical Group’s unique portfolio is ideal for automotive lightweight solutions such as carbon fiber, composites, high-performance TPOs and PPs, TPEs and TPVs, and engineering plastics. As a solution-driven partner, we will bring together high-performance materials, engineering processes, and innovative design expertise to help you transition into more sustainable exterior automotive material solutions.

Body panels pull double-duty on vehicles, creating aesthetics while protecting the passengers. These multi-functional pieces are challenged with some of the most stringent safety requirements as well as maintaining exceptional performance and reliability. With the amount of material used for these panels, lightweighting can play a significant role in reducing greenhouse gas emissions, making carbon fiber composites a natural fit. Mitsubishi Chemical Group is poised to ensure continuity of supply and quality with the only fully integrated carbon fiber value chain globally.

Critical to passenger safety, vehicle front lighting demands innovative materials that can withstand severe weather exposure while maintaining pristine clarity and transparency for years. Mitsubishi Chemical Group leverages decades of material science in automotive applications and a passion for innovation to continually develop next-generation lighting materials to provide the ultimate safe driving experience.

Rear lighting presents more challenges and material requirements than other vehicle portions. However, utilizing PMMA lens covers offers one of the most significant opportunities for truly circular materials. As one of the premier suppliers of PMMA globally, Mitsubishi Chemical Group is pioneering the chemical recycling of PMMA to deliver fully recycled materials with virgin quality.

With future demands of exterior lighting to communicate with pedestrians and other vehicles, developing materials for light diffusion, edge lighting, light guides, and selective light transmittance are challenging OEMs like never before. Mitsubishi Chemical Group’s material engineers partner with customers to develop new materials for their most challenging lighting applications, delivering products that endure through time and the elements.

Moving components responsible for vehicle opening and closures must endure abuse from the elements and passengers alike. Therefore, durability is critical in performance to ensure functionality and driver safety. Utilizing glass, carbon fiber, and other innovative composites, Mitsubishi Chemical Group can deliver high-performance, lightweight, and durable materials.

Perfecting exterior aesthetics through compounding expertise and master batch color matching are core technologies that differentiate Mitsubishi Chemical Group in the automotive space. In addition, our material experts partner with customers to customize trim materials with a focus on lightweight and process elimination, delivering high-performance, high-value, sustainable solutions.

Automotive seals transform the driver experience, protecting from noise and the elements. These materials must stand the test of time without any physical changes or property degradation. Mitsubishi Chemical Group is a premier global partner, working with OEMs and Tiers to develop high-performance material solutions for critical seal applications.

Vehicles are more connected than ever, sensing the surrounding environment to ensure passenger safety. From basic lens covers to millimeter wave RADAR emblems, RADAR/LiDAR absorbing materials, and integrated antennas, Mitsubishi Chemical Group is at the forefront of material technology development to deliver the future of the connected vehicle exterior.

When considering vehicle assembly, transportation, and repair, ensuring the protection of wheels, body panel edges, and other delicate surfaces is critical. Mitsubishi Chemical Group has developed a multi-purpose protection and repair tape that is easily applied and removed without residue. This innovative technology is hand-tearable, eliminating the need for a knife or sharp tool. Additionally, it is easily repositionable, which reduces waste.

Ask our experts about Exterior Material Solutions, today!