Discover Mitsubishi Chemical Group: Making the materials that make cars

We partner with the world’s most innovative automotive manufacturers and OEMs: supporting your growth and solving your industry challenges.

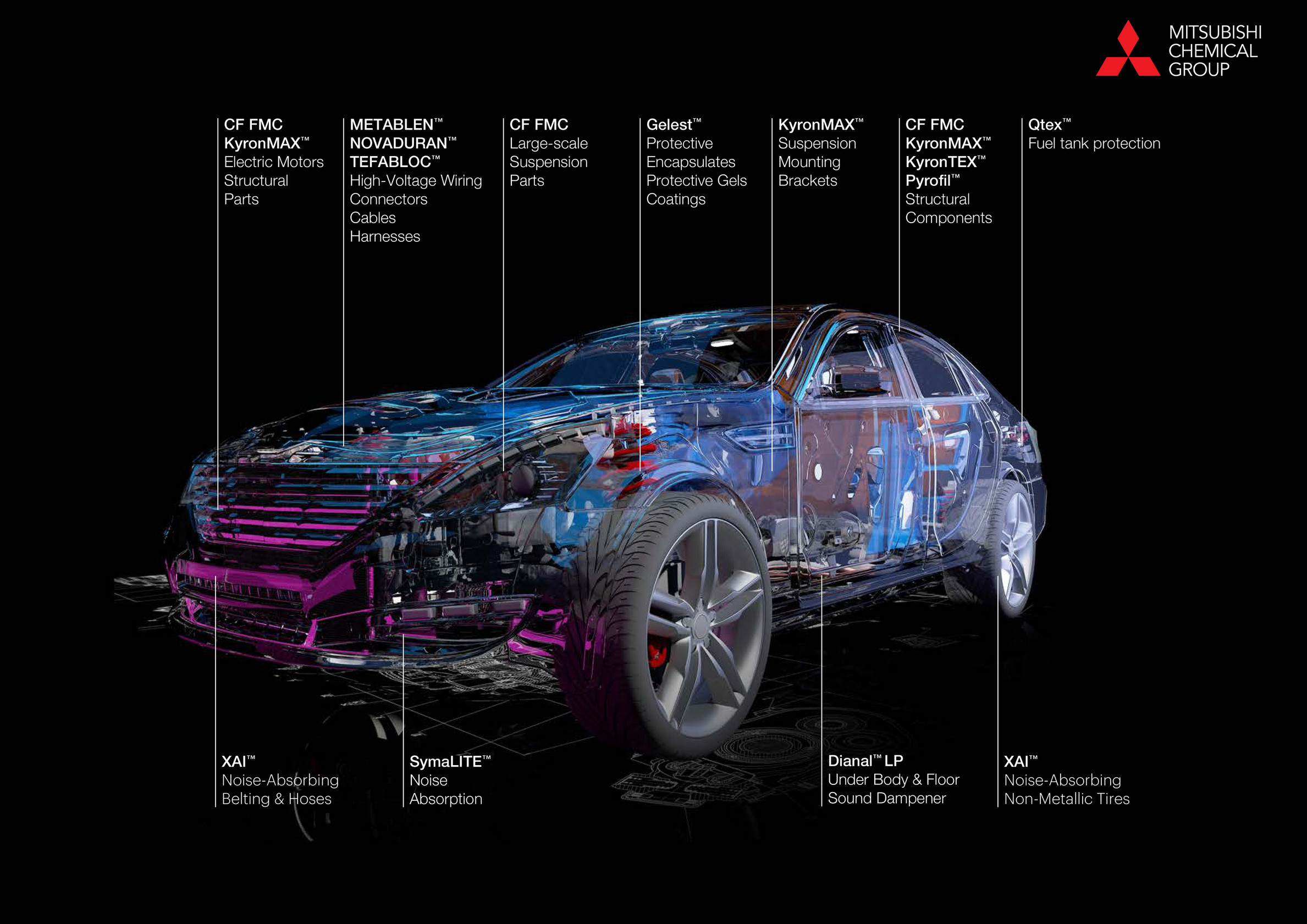

MCG materials: integral to the automotive landscape

Mitsubishi Chemical Group has been partnering with the world’s leading automotive manufacturers, OEMs and tier suppliers for more than fifty years. We may not always be in the limelight, but we’re always there, supporting business growth and solving your toughest challenges by applying a unique blend of global cross-industry expertise, material science, engineering processes, and groundbreaking design. The result? Powerful collaborations with you; producing innovative and high-performing solutions for today – and for tomorrow.

Engineering the innovative solutions of today and tomorrow

We manufacture high-performance materials that enable you to achieve your product goals for durability, safety, and sustainability. Many MCG innovations have gone on to become recognized market leaders – for example, MCG is now one of the leading global suppliers of airbag materials – and we’re a driving force in

shaping the future of sustainable mobility.

Example: replacing metal structural and semi-structural vehicle parts with lighter, safer composite

materials

MCG’s lightweight moldable and injectable thermoplastic, KyronMAX®,enabled Jeep® to replace metal in their roof receivers by delivering the necessary strength, ductility, fiber loading, and flexibility that previous polymer solutions had lacked. Recognized for Innovation at the inaugural Stellantis Supplier Awards, our joint solution went on to win multiple highprofile industry awards that year.

Replacing metal with KyronMAX enabled Jeep to cut bracket weight by approximately 80%, and reduce their materials costs by 35%

Example: developing high-performing materials for hybrid and

electric vehicles

Our collaborations with customers have resulted in a wide range of e-mobility solutions for applications such as electric motor housings, thermal management and fire protection, and for providing the sound absorption and insulation vital for reducing NVH in quietly-operating vehicles.

The lightweight design, fire retardancy, and recyclability of our lightweight battery pack cover material has taken high voltage safety in e-mobility to a whole new level.

Strategies designed to support your business

Even as we continuously build on our capability for testing and manufacturing new products and solutions, we remain invested in automating and upgrading existing facilities to help maintain uninterrupted supply. This means you can rely on MCG’s resilience, just as much as you can on our innovation.

For example, we know that just-in-time manufacturing doesn’t work when supply chains are extended and unstable. Our regional strategy helps reduce this risk in the USA, covering our entire portfolio to provide incountry support. This localization, combined with global dual-sourcing, enables us to offer shorter lead times and aims to ensure greater consistency and reliability of supply for your business.

As automotive manufacturers continue to face pressures around data transparency, compliance, and managing costs without compromising quality, clear and dependable material data becomes increasingly important. Alignment with global industry standards is supported by MCG’s worldwide network; and made human for customers with consistent access to our team’s technical expertise.

Sustainability – in all its forms – remains central

As a global organization, we are committed to KAITEKI; using less to have more, for the well-being of people and the planet. These two goals are interdependent, solving social problems while delivering impressive results for you, our customer. This means we work closely with you to understand your vision, to help you achieve your materials goals for both sustainability and performance.

Our dedicated team of researchers and material scientists is developing innovative technologies and solutions to use valuable resources in a smarter way, while reducing overall environmental impact.

- LESS RESOURCE

We help to conserve resources by facilitating the transition to bio-based and recycled raw materials - LESS WASTE

We recycle, and partner with our customers to help them do the same - LESS IMPACT

We decrease environmental impact through our advanced resin innovation and development of lightweight materials - MORE PRODUCT LIFE

We enhance material properties to extend the useful life of products

MCG’s plant-based materials are now replacing conventional engineering polymers, helping reduce the consumption of fossil fuel-based raw materials. And our strong-but-lightweight composite and flameretardant materials are increasing passenger and driver safety while reducing energy consumption.

Example: Eliminating painting with partially bio-based engineering plastic

Multi-step painting and coating processes are emissions-intensive and generate waste – yet up until recently it has been difficult to deliver the desired aesthetics and durability of finish without them. Switching to DURABIO™, our 40-60% bio-based engineering plastic, means our customers can significantly reducing their environmental impact while still being able to achieve an excellent high-gloss surface and color finish that’s heat-, impact- and scratch-resistant.

Example: Switching to high-performance recyclable resin for vehicle interior surfaces

RIM injection-molded components aren’t usually recyclable, but TEFABLOC™ TESI 84 TPE is. This highperformance resin is the sustainable alternative to traditional materials such as silicone rubber or XLPE, and gives you excellent durability, flexibility, and ease of processing, while meeting safety standards and keeping environmental impact to a minimum.

Example: PFAS-alternative coating system for headlamps and exposed surfaces

ACRYKING™ is our advanced coating system that provides long-term protection against UV degradation and physical wear. It’s curable, weather- and scratch-resistant, and – unlike other solutions – free from PFAS and other harmful additives.

Our focus? Helping you achieve your goals

Mitsubishi Chemical Group offers an impressive portfolio of solutions for demanding automotive applications. Our brands and products are extremely wide-ranging, including those we’ve already mentioned, plus Thermorun™, Therminsynx™, Trexprene™, Novduran™ and many more – which is why we’re here to help you navigate to the right solution for your application.

Get in touch with us, and we’ll provide you with a single point of contact for all things MCG, ensuring conversations are focused firmly on your current product goals and objectives, and on the most relevant solutions and ideas for your business.

“We believe the best innovations are built together. That’s why we actively engage with our customers – from workshops to on-site visits – to align their goals with our materials expertise. At Mitsubishi Chemical Group, our teams are committed to co-developing the solutions that will drive safer, more sustainable mobility forward.”

Shujiro “Shu” Toyofuku

General Manager, Performance Polymers Division

Connect with your dedicated MCG team

MCG’s cross-industry innovation, global resilience, and deep investment in R&D make it possible for you to access the most effective and sustainable materials for your products. Collaborating with us means connecting with our powerhouse team of over 2,000 R&D and material science experts, plus a wealth of engineering processes to support your future-ready solutions.

With a focus on reducing environmental impact, we’ll work with you to develop highly innovative solutions with new levels of functional integration, solving your most challenging problems in a way that ensures mutual success.

Whether you’re exploring a new challenge or continuing an existing project, our account managers are here to support you. Simply reach out through the contact form and the team will connect you with the right expertise.